Royal Machine Mounts

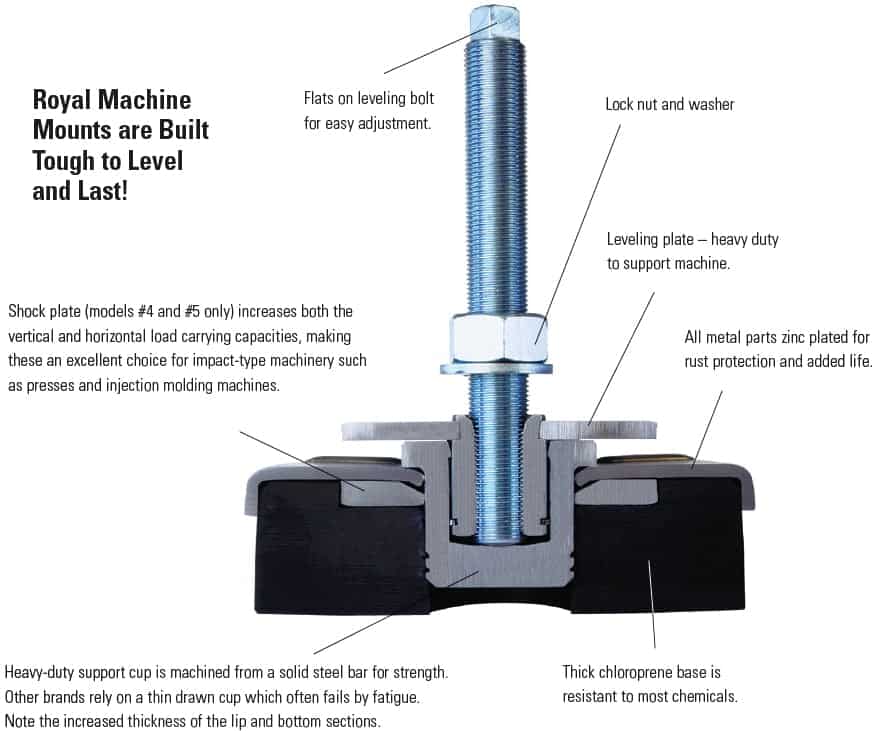

- Royal machine mounts are built tough to level and last. All metal parts are zinc plated for rust protection and long life.

- Royal machine mounts simplify machine installation, reduce noise, and isolate vibration.

- Great for injection molding machines, presses, lathes, mills, and grinders.

- These mounts meet OSHA requirements by preventing machines from “walking” without the need for bolting or cementing.

- All Royal machine mounts incorporate a large, chloroprene rubber base that is resistant to oil, water, and many chemicals.

- Support cup is machined from a solid bar instead of deep drawn, resulting in increased thickness for strength and rigidity.

- Unique internal retaining clip ensures that mounts will stay together if machine is moved to a new location.

- Royal machine mounts protect sensitive machine components, improve performance, and reduce maintenance costs.

Easy Installation — No drilling or bolting to floor required

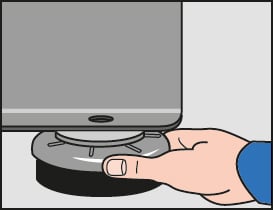

Raise machine and slide mount into place.

Insert leveling bolt through machine base hole and thread into mount. Lower machine onto leveling plate.

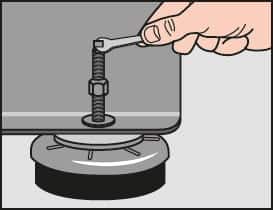

Raise or lower machine by turning leveling bolt.

When machine is level, secure in place with washer and lock nut.

Choosing the Correct Royal Machine Mounts

- Calculate the load on each mount by dividing the total weight of the machine by the number of mounting locations.

Note: sometimes it may be necessary to compensate for machines that do not have an evenly distributed load.

- Find the category in the specification chart which corresponds to the type of machine being installed.

- Match up the correct mount with the machine.

Example: Suppose you wish to mount an 18,000-lb. CNC lathe which has six mounting locations.

18,000 ⁄ 6 = 3,000 lbs. per mount

Using the chart below, we see that this machine falls into the range of the 27003 mount for non-impact machinery.

Warning: Always use the correct mount for each machine. These mounts are not designed for machines that must be bolted to the floor to prevent tipping. If you have any questions, please contact us.

Royal Machine Mounts

Filters Sort results

Reset Apply

Load Range General Non-Impact Machinery (lbs.) | Load Range Injection Molding Machines (lbs.) | Load Range Presses Up to 125 strokes / min (lbs.) | Load Range Presses Up to 180 strokes / min (lbs.) | Load Range Presses Up to 200 strokes / min (lbs.) | Base Diameter | Leveling Plate Diameter | Height to top of Leveling Plate | Height to top of Bolt | Leveling Bolt Size | Standard Leveling Bolt | Level Adjustment | PART NUMBER | PRICE | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

#1 | 100–1,100 | 390 max. | 150-440 | 130-300 | 110-260 | 3.16 | 2.38 | 1.63 | 5.25 | M12 x 1.25 | 4.72 | 0.88 | $57.00 | ||

#2 | 880–2,200 | 790 max. | 440-880 | 300-770 | 260-550 | 4.75 | 3.12 | 1.94 | 5.25 | M16 x 1.5 | 4.72 | 0.88 | $110.00 | ||

#3 | 1,760–5,500 | 2,180 max. | 880-3,080 | 770-2,420 | 550-1,760 | 6.31 | 3.93 | 2.31 | 7.50 | M20 x 1.5 | 6.88 | 1.00 | $158.00 | ||

#4 | 3,300–8,800 | 5,450 max. | 3,080-5,940 | 2,420-4,290 | 1,760-2,860 | 6.31 | 3.93 | 2.31 | 7.50 | M20 x 1.5 | 6.88 | 1.00 | $189.00 | ||

#5 | 6,600–12,000 | 8,220 max. | 5,940-8,800 | 4,290-7,700 | 2,860-5,280 | 7.88 | 3.93 | 2.72 | 7.88 | M20 x 1.5 | 6.88 | 1.00 | $308.00 |